This manual provides a comprehensive guide for installing and setting up the Allgaier Screen Tumbler, ensuring efficient operation and longevity of the equipment.

1.1 Overview of the Allgaier Tumbler Screening Machine

The Allgaier Tumbler Screening Machine is a high-performance solution for fine and ultra-fine screening of dry bulk materials. Utilizing advanced 3D motion technology, it ensures precise separation and high throughput. Its unique design, featuring anti-blinding devices like air knives and ultrasonic cleaners, prevents clogging and maintains efficiency. Ideal for various industries, the machine is known for its durability and ability to handle challenging materials effectively.

1.2 Key Features and Benefits

The Allgaier Tumbler Screening Machine offers high screening quality, up to seven separation fractions, and low acceleration for gentle material handling. Its advanced anti-blinding systems, including air knives and ultrasonic devices, ensure optimal performance. The machine’s robust construction and wide range of configurations make it suitable for diverse industrial applications, providing precise separation and minimizing dust generation for efficient and reliable operation.

Pre-Installation Requirements

Ensure a level, stable base and adhere to safety guidelines. Gather all tools and materials specified in the manual for a smooth installation process.

2.1 Site Preparation and Safety Considerations

Ensure the installation site is clear, level, and stable. Verify proper ventilation and electrical connections. Wear personal protective equipment and follow safety guidelines. Secure the area to prevent unauthorized access and ensure emergency exits are accessible. Adhere to local regulations and manufacturer recommendations for a safe and efficient setup process.

2.2 Tools and Materials Needed

Essential tools include wrenches, screwdrivers, and measuring instruments. Required materials are mounting bolts, electrical connectors, and lubricants. Ensure all components are compatible with the machine’s specifications. Refer to the manual for a detailed list to avoid missing critical items. Proper preparation of tools and materials ensures a smooth and efficient installation process.

Step-by-Step Installation Process

Follow a systematic approach, starting with machine assembly, then connecting electrical and hydraulic systems, and concluding with precise alignment and leveling for optimal function.

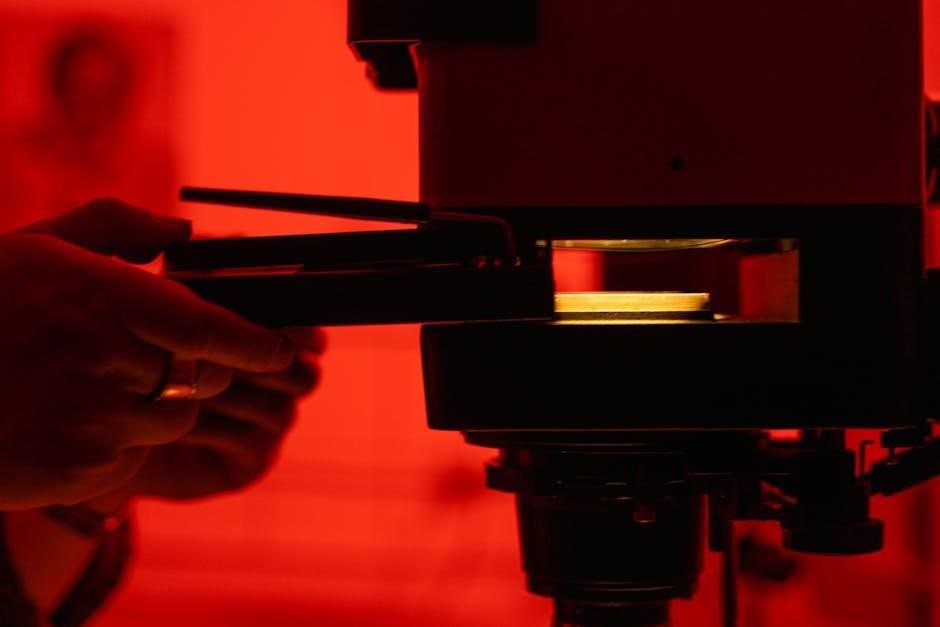

3.1 Assembly of the Tumbler Screening Machine

Begin by carefully unpacking and inventorying all components. Follow the manual to assemble the machine frame, ensuring all bolts are securely tightened. Install the screening decks, drive system, and anti-blinding devices according to specified torque values. Use the provided tools to ensure proper alignment and fitment of all parts. Refer to the manufacturer’s instructions for precise assembly steps to guarantee a stable and efficient setup.

Once assembled, inspect the machine for any loose connections or misalignments. Ensure all safety guards are in place and functional. The assembly process lays the foundation for smooth operation, so attention to detail is critical at this stage.

3.2 Connecting Electrical and Hydraulic Systems

Connect the electrical components according to the wiring diagram in the manual. Ensure all cables are securely fastened and grounded for safety. Power up the control panel and test the motor to confirm proper operation.

For hydraulic systems, attach the hoses to the designated ports, ensuring no leaks. Use the recommended hydraulic fluid and maintain the specified pressure. Test the system at low pressure before full activation to verify functionality and safety.

3.3 Final Alignment and Leveling

Ensure the Allgaier Screen Tumbler is properly aligned and leveled after installation. Use shims to adjust the machine’s base, ensuring even contact with the floor. Check the level using a spirit level, making adjustments as needed to achieve proper balance.

Tighten all base bolts securely once the machine is level. Verify that all components, including the screen and motor, are aligned correctly. Proper alignment ensures optimal performance and prevents potential damage from uneven operation.

Initial Startup and Testing

Power on the machine and run initial test cycles to ensure smooth operation. Monitor performance, check for vibrations, and verify proper material flow through the screen.

4.1 Powering On the Machine

Ensure all electrical connections are secure and the power supply matches the machine’s specifications. Press the power button to initiate startup. The system will perform a self-test. Monitor the control panel for any error messages. If no issues arise, the machine will enter operational mode. Always follow the manual’s guidelines for a safe and successful startup process.

4.2 Running Initial Test Cycles

Start by loading a small sample of material to test the machine’s functionality. Observe the screening process, ensuring smooth operation and consistent results. Check for any unusual noise or vibrations. If issues arise, refer to the troubleshooting section. Once the test cycle completes, inspect the machine and output quality to confirm optimal performance before proceeding to full-scale operation.

4.3 Adjusting Settings for Optimal Performance

Adjust the machine’s vibration settings and sieve inclination to achieve desired separation efficiency. Utilize the 3D motion technology to optimize material flow. Ensure anti-blinding devices, such as air knives or brushes, are functioning correctly to prevent clogging. Fine-tune the hydraulic system for smooth operation. Regularly monitor and modify settings based on material characteristics and output quality to maintain peak performance levels throughout the screening process.

Operation and Maintenance

This section outlines essential operational procedures and maintenance routines to ensure the Allgaier Screen Tumbler functions at peak efficiency and longevity, aligning with manufacturer guidelines.

5.1 Daily Operational Checks

Daily inspections ensure smooth operation. Check screen meshes for blockages, verify vibration amplitude, and inspect bearings for proper lubrication. Monitor motor temperature and belt tension, addressing any discrepancies promptly to prevent downtime and maintain efficiency. Regular cleaning of anti-blinding devices, like brushes or air knives, ensures optimal material separation. Record findings for routine maintenance planning and troubleshooting potential issues early.

5.2 Routine Maintenance Procedures

Regular maintenance ensures optimal performance. Schedule periodic lubrication of moving parts and inspect screen meshes for wear. Replace worn components promptly to maintain separation accuracy. Clean anti-blinding devices and check vibration motors for alignment. Inspect bearings and belts for wear, and replace as needed. Document all maintenance activities to track equipment health and plan future servicing effectively. Consistent upkeep prolongs machine lifespan and ensures reliable operation.

5.3 Troubleshooting Common Issues

Common issues include vibrations, reduced screening efficiency, or machine startup failures. Consult the manual for diagnostic guidance. Check power supply and electrical connections if the machine fails to start. Inspect screen meshes for blockages and clean or replace them as needed. Ensure anti-blinding devices are functioning properly to prevent material buildup. Address any imbalance in the machine by adjusting weights or alignment. Regularly check for worn parts and replace them promptly to maintain performance.

Safety Precautions and Best Practices

Always wear protective gear, including gloves and safety glasses, when operating the machine. Ensure proper training for operators and follow emergency shutdown procedures. Regularly inspect equipment for wear and tear. Maintain a clean workspace to prevent accidents. Adhere to all safety guidelines outlined in the manual to ensure safe and efficient operation of the Allgaier Screen Tumbler.

6.1 Operator Safety Guidelines

Operators must adhere to all safety guidelines to ensure safe operation of the Allgaier Screen Tumbler. Always wear protective gear, including gloves and safety glasses. Ensure proper training before operating the machine. Familiarize yourself with emergency stop locations and procedures. Avoid loose clothing that could get caught in moving parts. Regularly inspect equipment for wear and tear. Maintain a clean workspace to prevent accidents and ensure optimal performance. Follow all safety protocols outlined in the manual to minimize risks and ensure a safe working environment.

6.2 Emergency Shutdown Procedures

In case of an emergency, activate the emergency stop button immediately to halt the machine. Ensure all personnel are at a safe distance. Do not restart the machine until the issue is resolved. Regular inspections can prevent emergencies, and only authorized personnel should perform shutdowns. Follow proper restart procedures after resolving the issue to ensure safe operation. Always prioritize safety and adhere to the manual’s guidelines.

Warranty and Manufacturer Support

The Allgaier Screen Tumbler is backed by a comprehensive warranty, ensuring coverage for parts and labor. Dedicated support teams are available for technical assistance and repairs.

7.1 Understanding the Warranty Terms

The Allgaier Screen Tumbler is covered by a comprehensive warranty, ensuring protection for parts and labor under specified conditions. The warranty period typically lasts for a defined duration, such as one year from installation, and includes coverage for manufacturing defects. Proper installation and maintenance, as outlined in the manual, are essential to uphold warranty validity. Manufacturer support extends beyond the warranty, offering access to genuine spare parts and expert technical assistance for optimal machine performance and longevity.

7.2 Contacting Allgaier Support

For assistance, contact Allgaier support via phone, email, or through their official website. A dedicated team is available to address technical inquiries, provide troubleshooting guidance, and offer spare parts support. Ensure you have your machine’s serial number and details of the issue ready for efficient resolution. Visit the Allgaier website for regional contact information and support resources.

- Phone: [Insert contact number]

- Email: [Insert email address]

- Website: [Insert website link]

This manual ensures your Allgaier Screen Tumbler operates at peak performance. Follow its guidance for longevity and efficiency, maximizing your screening processes effectively.

8.1 Summary of Key Installation Steps

The Allgaier Screen Tumbler installation involves preparing the site, assembling the machine, connecting electrical and hydraulic systems, and aligning the equipment. Conduct initial tests, ensure proper leveling, and follow safety guidelines. Adhere to the manual for optimal performance and longevity. Regular maintenance and compliance with manufacturer instructions are crucial for efficient operation.

8.2 Final Checks and Handover

After installation, perform a thorough inspection to ensure all components function correctly. Verify electrical connections, hydraulic systems, and machine alignment. Conduct final tests to confirm optimal performance. Document the setup and provide operator training. Hand over the machine with all necessary manuals and maintenance schedules, ensuring smooth transition to routine operation.